With the designed construction material for durability and recycling ease, like “mud – house construction“, can dramatically save our natural resources and reduce energy demand. The mud – house uses minimal energy, is comfortable year round. Moreover, it is easily to build. Anyone can create any shape of their own buildings or community can participate without constructor payment bills.

Mud

Mud as worthy construction material

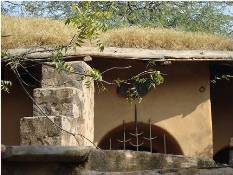

Due to one man’s persistent, wise, skilful and persuasive efforts, mud has been restored to its rightful status as a worthy construction material that can help produce durable houses and dwellings for both rich and poor. Architect Laurie Baker spent lonely and long years perfecting the skills required to build lasting mud houses.

More people in India today live in houses constructed out of mud than out of any other material. Most of these houses have been built by those who live in them, with the assistance of persons skilled in the use of mud as a building material.

Elegance without Extravagance

Contrary to popular perception, mud houses are affordable to all classes and can be designed to suit different tastes and fancies. They are environmentally virtuous and can face the elements with as much hardiness as supposedly stronger constructions made from concrete.

For those not yet fixated on the inevitability of the use of modem materials and on their much vaunted strength, mud houses can be a liberating way to meet housing needs, private and public, without extravagance but with elegance.

Mud is the natural building material

Mud is the natural building material, mud is harmonized with all environments and good for being a passive air-conditioning system.

Thus living in mud-house is comfortable year round. Frugality and reuse in mud house construction can create tremendous saving in environmental impact, energy use and capital expenditure.

It can be found mostly in hot-dry and arid area like some parts of India, Nepal, China, African continent and even in the West Side of North and South American continent.

Mud brick vaults and domes are common in countries like Iran and Egypt. Many communities in the north and northeast of Thailand also live-in and build their dwellings with mud.

All mud-house constructions use just simple local materials, mainly are soil and water, added up with paddy husky or rice straw or local fiber weed. The subordinate materials can be anything from garbage recycling, such as bottles, cans, newspaper, etc. Besides that, the mudded walls are mostly massive, which help a year around stabilize temperature inside houses of about 24°c to 26°c. [ 2 ]

Mud-house construction.

The mud – house uses minimal energy, is comfortable year round. The building is massive construction technique, mainly because of the temperature extremes and its unique earth – sheltered design. All exposed mud walls are built like a thermos or burnt earth bottle. A passive air – conditioning system supplies cool air to the house through these massive mud walls.

The mud – house construction uses only simple natural materials, which are any digging soil from the earth mixed with water and added up with paddy or hay or any dried fiber or even recycling garbage. That means our scare natural resources like cement, rocks, metal from the mountains, and wood from the forests not to be used.

Construction Techniques

There are seven types of mud-house construction.

1. Adobe

Sun-dried brick [soil & water & local fiber materials] bonded with clay mortar; wall baring system.

Moulds of brick are filled with the right mix of wet mud. The mould is then removed and the brick dried in the sun. This is the most popular form of brick-making since it uses only solar energy, which is free. Recently, developers have invented a machine which can be used to produce compressed mud bricks. However, the machine is quite exhausting to operate as one must use muscle power to do the compression. However, the bricks that come out of the process have a fine smooth finish and walls using such bricks can take the load of a three-storeyed house

Cob

Fresh lumps of mud [soil & water & local fiber materials] stacked on each other; wall baring system.

Large lumps of mud are moulded in the shape of a huge elongated egg, about 6 inches in diameter and about 12 to 18 inches in size. Rows of cobs are placed over each other to make a wall. Gaps and holes are filled and the wall is slammed down at the sides.

The cob system is the easiest for those constructing a mud house for the first time and no special tools, equipment or moulds are required.

Wattle and Daub

Woven work of sticks intertwined with twigs or bamboo covered with mud; framework system.

This is used particularly for meeting housing requirements in areas prone to cyclones or earthquakes. Wattle is used to form the structure of the house and mud is used to daub the walls. During the rains, the daub may be washed away but it is easily replaced. The wattle can withstand any earth tremors.

Cordwood or Stone

Left over materials like slender shoot of a tree or tiny stone bonded with mud [soil & sand & paddy husk]; wall-baring system.

Rammed Earth

Damp earth lay between formwork and mould and compacted by ramming; wall baring system.

Here, one requires wooden equipment, because the principal merit of the system is that the earth is packed hard by ramming, making the walls exceedingly strong. Basically, the process involves two parallel planks held firmly apart with metal rods and bolts. Mud is thrown into the space between the planks and then rammed down with either a wooden or a metal ramrod. Once a layer is completed and has hardened, the planks are released, taken high up and the next layer is installed

Earthen Bag

Stacking the sags of damp earth hooked up with thorn or barbed wire; wall baring system.

Straw-bale

Plastering the bundle of hay with mud; the structure can be both skeleton and wall baring system.

Advantages of mud as construction material

Environmental impact :To save natural resources

- Using neither cement nor rock (Save our mountains)

- Using just a little wood (Save our forests)

To save building materials –

- Main materials are soil and water, mixed to be mud, if the mud is too sticky, we can add up with paddy husky or rice straw or local fiber weed or bamboo.

- Subordinate material can be any garbage for recycling (bottles, cans, newspaper, etc.)

To save energy

- Cool in summer (Inside building temperature is about 24°c to 26°c).

- Warm in winter (Automatic temperature control by passive cooling

- system)

Capital expenditure : · To save money

- No air – conditioning, no electricity bills

Long life buildings (Djeme mosque in Mali, Africa was built in 13th century, and Lakeland farmhouse in Lake District, U.K. has been growing steadily since 1603)

IS 13077 : 1991

Selection Of Clay For Mud Mortar

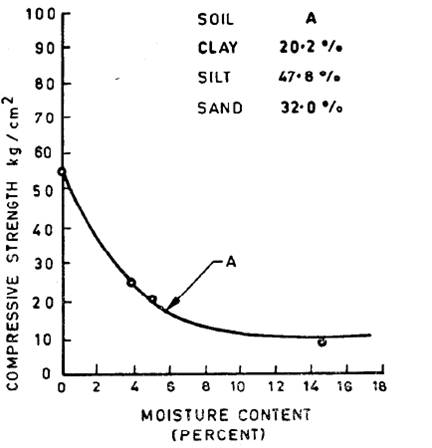

The clay or mixture of clays should preferably conform to the following mechanical composition % by Weight.

Grain size analysis shall be done in accordance With the method given in IS 2720 (Part 4 ) 1986

- Clay 18-22 %

- Silt 40-45 %

- Sand 30-40 %

The total content of clay and silt be preferably not less than 60 percent by weight.

In case of soils which are more sandy or clayey than the limits specified above, the same should be blended with more plastic clay or nonplastic materials as the case may be so as to bring the mechanical composition within the above specified limits.

Design Consideration

The durability of masonry mortars depends upon the volume changes during the process of setting, hardening and later due to temperature variations, moisture movement in the surrounding, changes in its own moisture content and the extent to which mortar will internally accommodate the stresses induced by these volumetric changes before yielding.

The compressive and bond strength of mud mortar decreases with the increase in moisture content in it. The compressive strength decreases by 0.8 to 1 N/mm2 at 6-10 percent moisture content

The bond between the mortar and masonry units if ruptured by the volumetric changes and the structural movements results not only in reduction in strength of masonry but also in formation of channels of seepage of water and other solutions into the masonry. This would aggravate the process of deterioration and affect resistance to chemical attack in aggressive environment.

Moisture to the extent of 5 to 8 percent by weight is likely to penetrate in the mud mortar even after plastering or pointing the exposed surface of masonry.

Basic stress in masonry with bricks of 7 to 10 N/mm2 and 3.5 N/mm2 shall not exceed 0.2 N/mm2 and 0.1 N/mm2, respectively.

Thickness of mud mortar should not be more than 20 mm in case of brick masonry works and 30 mm in case of stone masonry works.

Preparation Of Mortar

The soil for preparation of mud mortar should be processed so as to be free from gravel coarse sand ( particle size greater than 2 mm ) lime and kankar particles vegetable matter, etc.

Coarse grit, karkar, etc, if present should be removed by wet sieving.

The sieved clay should be allowed to dry and then blended with plastic clay or a nonplastic locally available material ( like rice husk, jute waste, wheat husk, etc ) as the case may be, so as to bring the mechanical composition within the limits Where wet sieving is not necessary, the soil shall be lightly broken up and wetted. The wet mass shall be tempered over under the feet, repeatedly turned over big spades and then thoroughly kneaded. The kneaded mass shall than be left for tempering for at least 24 hours with the soil being preferably covered with wet gunny bags.

Immediately before use in the masonry a small quantity of the prepared soil shall be mixed with a further quantity of water to obtain the desired consistency and workability. The total moisture content of the prepared mortar shall be in the range of 35 to 40 % by weight of soil.

Field Test Of Mud Mortar

- The soil should be ground to a fine powder and mixed with sufficient water, added in small quantities. The mix should then be kneaded into a plastic mass of the required consistency.

- Take a handful of the soil prepared AND FORM A BALL OF ABOUT 80MM DIAMETER

- Keep the ball in the sun for drying when dried, examine the ball for loss of shape and surface cracks, if any.

- If the ball prepared has deformed on drying and crumbles easily when pressed lightly, it may be inferred that sand content is excessive.

- If the ball is hard but shows cracks on the surface, then the sand content is insufficient.

- If the soil is not found suitable, as inferred above, the test should be repeated after modifying the composition of the soil, such as by mixing different proportions of two soils or by addition of sand or clay whichever is needed, for checking the stability.

IS : 2115 – 1980 : Laying Mud PHUSKA in flat roofs.

Mud PHUSKA – An insulating medium in roof finish of a layer of compacted soil underlying another layer of soil mixed with building material such as cowdung and fibrous reinforcing ingredient such as wheat straw.

Mud PHUSKA is a common type of insulating course in the roof used in hot dry regions of the country, such as in the states of Punjab, Uttar Pradesh and other regions where the rainfall is not heavy.

Its use is cheap, reasonably durable and adds enough thermal insulation for maintaining relatively comfortable temperature in the interior. In laying the roof, however, there are several important details of workmanship which, if neglected, will considerably reduce the efficacy of the roof.

IS : 2115 – 1980 : Protection Against Water Penetration.

Mud PHUSKA layer by itself may not be sufficiently waterproof for the roof and it may be necessary to provide beneath it a waterproofing layer or membrane to be effective in this respect. Care shall also be exercised while doing the roof finish work to compact the mud PHUSKA layer to the maximum density

The slope of the terrace shall be such as to drain off promptly all rain-water falling on the roof surface well before the water begins to seep through cracks, if any, into the mud PHUSKA layer. The slope shall not be less than 1 in 40. If it is not possible to give all the slope by the mud PHUSKA layer, part of the slope required for roof drainage may be given in the sub-floor itself.

Rain-water pipes to be provided for roof drainage shall be determined in accordance with the intensity and duration of the rainfall in the area. The cross-sectional area of flow of the rain-water pipe shall be not less than l/5000 of the roof area drained, and the pipe shall in no case be less than 100 mm diameter.

IS : 2115 – 1980 : The Material.

Soil for Mud PHUSKA – The soil for mud PHUSKA shall be free from gravel and coarse sand (of particle size greater than 2 mm ), vegetable matter and fine KANKAR particles. The coarse material shall not exceed 25 percent by mass. The soil shall also be free from harmful and efflorescent salts.

- NOTE 1 -Generally soil suitable for brick making is suitable for mud PHUSKA also.

- NOTE 2 -Soils collected from localities afflicted by white ants may not be suitable.

- NOTE 3 – The above plasticity index will indicate a reasonable cohesive soil.

Mud plaster : The dry soil shall be reduced to fine powder and mixed with water in a pit, adding wheat straw 6 percent by mass and cowdung 12 percent by mass. The mixture shall be allowed to rot for a period of not less than 7 days. During this period, it shall be pugged manually using spades if necessary to get a homogeneous mass free from lumps and clods.

Cut-Back Bitumen – Cut-back bitumen shall be prepared by adding 20 parts of kerosene oil and 1 part of paraffin wax to 80 parts of 80/100 bitumen melted on gentle fire. The mixture shall be worked to a homogeneous mass. Information on this site is purely for education (students / users) purpose. The materials used and displayed on the Sites, including text, photographs, graphics, illustrations and artwork, video, music and sound, and names, logos, IS Codes, are copyrighted items of respective owners. They are provided here just for refrence/information.

For your views and discussions Register in FDAchitects Forum …